PRODUCTS

Significant Features of Wear Resistant Compound Steel Wear Plate

1. The chemical composition of the high wear-resistant alloy layer is 4-5% in carbon content and 25-30% in chromium content. The volume fraction of Cr7C3 carbide in the metallographic structure is more than 50%, the macro hardness is hrc56-62, the hardness of chromium carbide is hv1400-1800, which is higher than that of quartz in sandstone, hv800-1200. As carbide is distributed vertically in the direction of wear, even compared with the cast alloy with the same composition and hardness, the wear resistance is more than doubled The comparison of wear resistance with several typical materials is as follows:

(1) with low carbon steel; 20 ~ 25:

(2) with high manganese steel; 5-10:

(3) with tool steel; 5-10:

(4) as cast high chromium cast iron; 1.5 ~ 2.5:

2. Good impact resistance: the bottom layer of wear-resistant composite steel plate is low carbon steel or low alloy. Stainless steel and other ductile materials reflect the advantages of bimetal. The wear-resistant layer resists the wear of wear medium. The substrate bears the load of medium, so it has good impact resistance. It can bear the impact and wear of high drop hopper in material conveying system.

3. Good heat resistance: the wear-resistant layer is recommended to be used under the working condition of ≤ 600 ℃. If vanadium, molybdenum and other alloys are added to the alloy layer, it can withstand high temperature wear of ≤ 800 ℃ The recommended operating temperature is as follows: the common carbon steel substrate is recommended to be used under the condition of not higher than 380 ℃; the low alloy heat-resistant steel plate (15CrMo, 12Cr1MoV, etc.) substrate is recommended to be used under the condition of not higher than 540 ℃; the heat-resistant stainless steel substrate is recommended to be used under the condition of not higher than 800 ℃.

4. The alloy layer of good corrosion-resistant and wear-resistant composite steel plate contains high percentage of metal chromium, so it has certain rust prevention and corrosion resistance. It can prevent coal sticking when used in coal chute and funnel.

5. It has a wide range of specifications and varieties, and has become a series of commodities. The thickness of wear-resistant alloy layer is 3-20mm. The thickness of composite steel plate is 6mm, unlimited. The standard wear-resistant composite steel plate can be provided with 1200 or 1450 × 2000mm, or can be customized and processed according to the drawing size according to the user's requirements. Wear resistant composite steel plate is divided into three types: ordinary type, impact resistant type and high temperature type.

6. The convenient processing performance wear-resistant composite steel plate can be cut, leveled, punched, bent and curled. It can be made into flat plate, arc plate, cone plate and cylinder. The cut composite plate can be welded into various engineering structures or parts. The composite plate can also be heated and pressed into a complex shape with a mould. Wear resistant composite steel plate can be fixed on the equipment by bolts or welding, which is convenient for replacement and maintenance.

7. Although the manufacturing cost of high price performance is higher than that of wear-resistant composite steel plate, its service life is increased several times, which greatly reduces the maintenance cost and downtime loss, and its price performance is about 2-4 times higher than that of ordinary materials. The greater the material handling capacity, the more serious the equipment wear, the more obvious the economic effect of using wear-resistant composite steel plate.

-

On-site training. More insight into the applications, more development.

2019-10-19 -

Safety is no small matter. Make safety your first thought and take precautions from tiny things.

2019-10-19 -

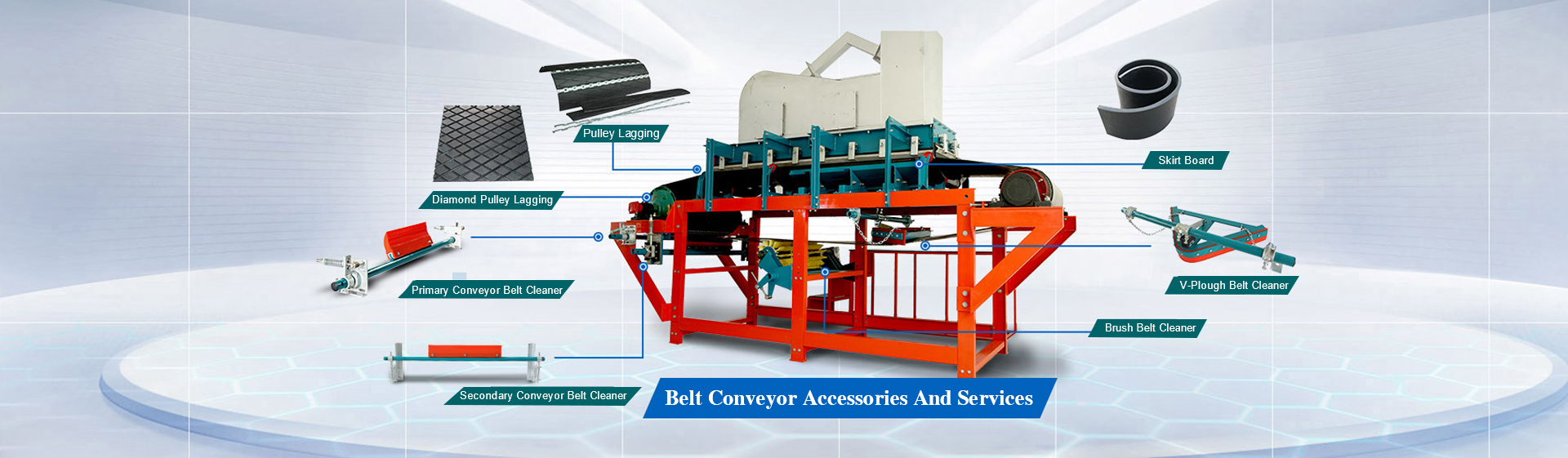

What Is Pulley Lagging

2019-10-21 -

Introduction of Pulley Lagging Installation Procedures

2019-10-21 -

Factors Affecting Wear Resistance of Pulley Lagging

2019-10-21 -

Advantages of Pulley Lagging

2019-10-21 -

Introduction of Wear Liners

2019-10-21

-

Significant Features of Wear Resistant Compound Steel Wear Plate

2019-10-21 -

Introduction of Conveyor Skirt Board and How to Install it

2019-10-21 -

Introduction of Belt Cleaner

2019-10-21 -

Features and Types of Belt Cleaners

2019-10-21 -

Introduction of Impact Bed

2019-10-21 -

Advantages of Impact Bed

2019-10-21 -

Design of Impact bed

2019-10-21